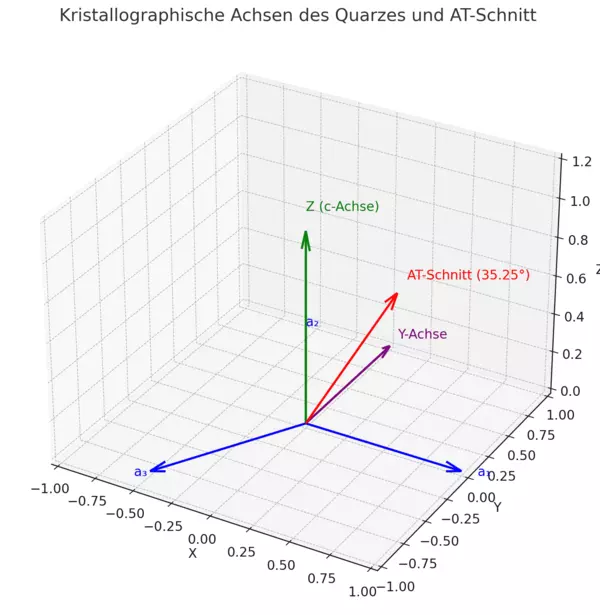

This explanation describes the crystallographic axes of a synthetic quartz crystal and the different types of cut (AT, BT and SC cut) used in the production of quartz crystals.

1. crystal structure of quartz

Quartz (SiO₂) crystallises in the trigonal crystal system. The structure consists of a network of SiO₄ tetrahedra arranged in a spiral along the Z-axis (also known as the c-axis).

2. crystallographic axes

A synthetic quartz crystal has the following main axes:

- a₁-, a₃-, a₃-axes (x-axes): In one plane, 120° to each other.

- Z-axis (c-axis): Corresponds to the optical axis.

- Y-axis: Electrical axis, perpendicular to the Z-axis.

3. AT section

The AT section is an inclined section (approx. 35.25°) against the Z axis in the X-Z plane. It is used to produce temperature-stable oscillating crystals. The oscillation takes place in the plate plane (planar mode).

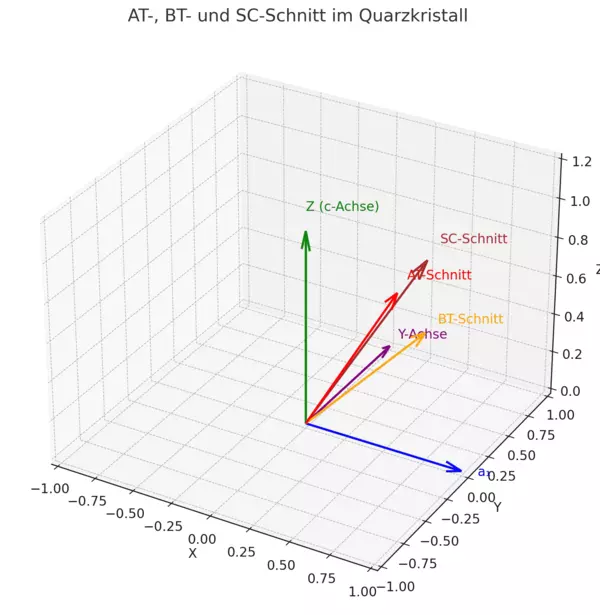

4. other quartz cut types

A comparison of the most important cut types:

Feature | AT cut | BT cut | SC cut |

Cutting angle | ~35.25° against Z | ~49° against Z | ~34° against Z, 22.5° against Y |

Temperature behaviour | Very good | Medium | Excellent |

Frequency stability | Good | Medium | Very high |

Mechanical stability | High | Slightly lower | Very high |

Application | Standard oscillating crystals | Watches, favourable | Space travel, precision devices |

6. use - which quartz cut is used where?

AT-Cut

The AT-Cut is the most widely used crystal cut for quartz crystals and is used to manufacture all our LRT (LOW ESR Resonator Technology) quartz crystals. AT-Cut crystals are characterised by good temperature stability, low frequency drift and a wide range of applications. AT-cut crystals can be miniaturised very well and are ideal for resonant crystals in the 3.2 - 285 MHz range.

The frequency tolerance at +25°C for our AT-Cut quartz crystals is ±10 ppm at +25°C. Ageing is in the range of ±10 ppm after 10 years. Over the temperature range of -20/+70°C, the narrowest possible temperature stability is ±10 ppm, over -40/+85°C ±15 ppm, over -40/+105°C = ±30 ppm, and ±50 ppm over the temperature range of -40/+125°C.

The AT oscillating quartz crystal therefore fulfils all requirements, even for very precise radio applications (ISM band, WiFi, etc.).

BT-Cut

The BT-Cut is an old cutting angle and was used in the past when the AT cutting angle was not yet so highly developed. BT-Cut oscillating crystals had greater temperature stability than AT-Cut crystals, but could be manufactured more cheaply in a wide range of frequencies than AT-Cut crystals. BT-Cut quartz crystals are no longer manufactured today - they have been completely replaced by AT-Cut quartz crystals.

SC-Cut

The SC-Cut cutting angle (Stress Compensated Cut) is a double-rotated quartz cut that offers excellent temperature stability, very low ageing and extremely high long-term stability. It is used in particular in precision oscillators such as OCXOs, where the smallest frequency deviations are critical (e.g. in telecommunications, 5G, GPS references, measurement technology, etc.).

OCXOs are Oven Controlled Crystal Oscillators, where an internal "oven" is used to keep the SC-cut crystal at a constant ideal temperature. This ideal temperature is in the range of 80 - 85°C where the SC-cut crystal also has its 0-cycle. Another special feature of the SC-Cut quartz crystals in OCXOs are the oscillation modes. For example, in OCXOs, SC quartz frequencies with 5 or 10 MHz are not realised in the fundamental, but in the 5th harmonic. Why? It's about the C1 or dynamic capacitance. A crystal in the 5th overtone has a much smaller C1 than a fundamental crystal, so that the SC cut crystal in the OCXO oscillates much more accurately.