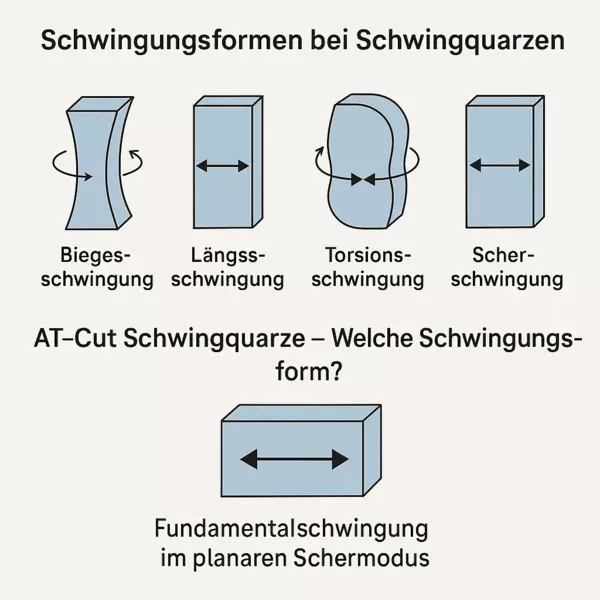

Vibrating crystals can be operated in various mechanical vibration modes. These differ in terms of their geometry, frequency characteristics, temperature behaviour and suitability for certain applications.

1. bending vibration (flexure mode / bending mode)

- Frequency range: typically < 100 kHz

- Use: mostly in tuning fork crystals with 32,768 kHz

- Advantages: low power consumption, compact

- Special feature: mechanically sensitive to shock and vibration

2nd longitudinal mode (longitudinal oscillation)

- Frequency range: mostly in the kHz to low MHz range

- Direction of oscillation: along the longitudinal axis of the quartz crystal

- Typical cuts: X-cut, Y-cut

- Disadvantages: relatively strongly temperature-dependent

3. torsional oscillation (torsional mode)

- Rather rarely used

- Torsional vibration around the crystal axis

- Complex geometry and difficult to control

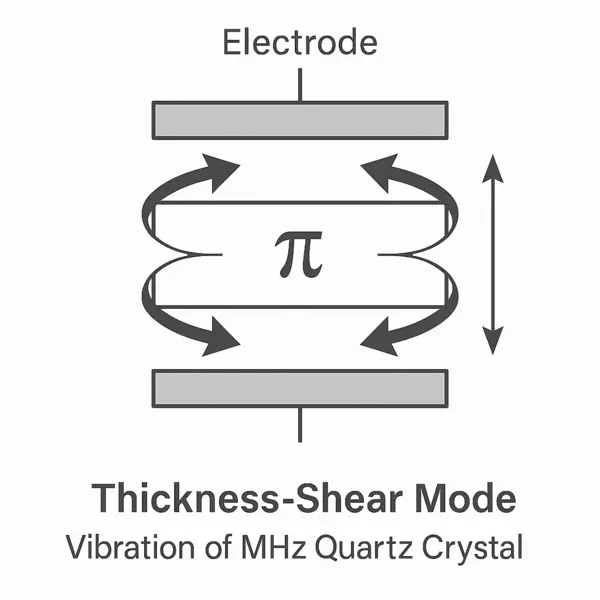

4. shear mode (normally used with MHz quartz crystals)

- Most important mode for high-frequency applications

- Typical cuts: especially AT cut, also BT cut

- Direction of movement: displacement of parallel crystal planes against each other

Advantages: low temperature dependence, high frequency stability

The picture shows an example of the different vibration modes of quartz crystals: