1. history of synthetic quartz production

Early use of natural quartz

- Until the middle of the 20th century, natural quartz was predominantly used - e.g. from deposits in Brazil, Madagascar or the USA.

- The demand for high-purity, low-defect and specifically orientated quartz for oscillating quartz crystals increased massively, particularly during the Second World War (radar, radio technology).

- However, natural quartz often showed inclusions, lattice defects or twinning, which led to unstable frequencies.

Development of synthetic quartz crystals

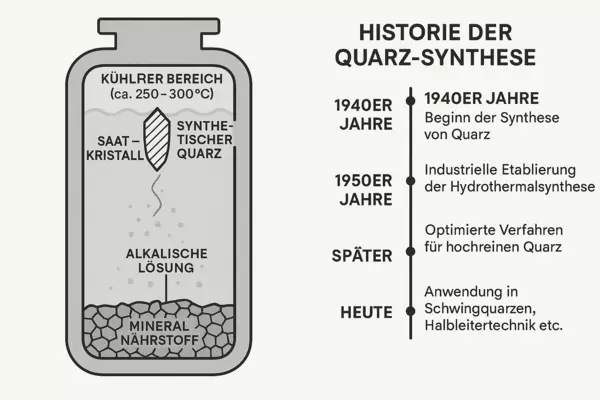

- In the 1940s, the synthesis of quartz began in so-called hydrothermal plants - a process that imitates natural growth conditions.

- From the 1950s onwards, hydrothermal synthesis was established on an industrial scale.

- Later, the process was optimised to produce high-purity and defect-free quartz blocks, primarily for semiconductor and frequency technology.

2. production of synthetic quartz blocks

Basic raw material

- The base material is high-purity silicon dioxide (SiO₂) - e.g. in the form of natural quartz, amorphous silica or purified silica from chemical processes.

- Extremely low impurities are crucial for electronic applications (ppb range, especially for Al, Na, Fe).

The hydrothermal process

The principle

- Simulation of geological conditions: high pressure, high temperature, water-based solution.

- Similar to the autoclave process used for synthetic gemstones.

Process steps

- Autoclave preparation:

- A pressure-resistant reactor (autoclave) is filled with a mineral nutrient (e.g. pulverised natural quartz) and an alkaline solution (usually NaOH or Na₂CO₃).

- Temperature gradient:

- In the lower part: higher temperature (approx. 350-400 °C) → where the SiO₂ dissolves.

- In the upper part: cooler (approx. 250-300 °C) → SiO₂ crystallises there.

- Germination insert:

- Seed crystals of quartz with a defined orientation are inserted at the top of the autoclave, on which the dissolved silicon dioxide grows.

- Crystal growth:

- Duration: several weeks to months.

- Result: synthetic single-crystal quartz with high structural perfection.

3. properties & quality

Advantages of synthetic quartz:

- High purity (few ppm/ppb impurities).

- Controlled crystal orientation (e.g. AT or BT cut for oscillating quartz).

- No twins or inclusions as with natural quartz.

- Reproducibility of physical properties.

Cleaning

- In some cases, the starting material is purified again by chemical cleaning or zone-melting processes before growth.

Utilisation

- Quartz oscillators / quartz crystals: Frequency-stable oscillators for all applications in electronics

- Semiconductor industry: Quartz glass made from synthetic quartz (e.g. for reactor tubes).

Optics: Lenses, prisms made of crystalline quartz.

We check every quartz ingot 100% during the incoming goods process. The purity and the corresponding crystallographic axes are checked optically (X-ray process). The quartz ingot is then given a prefixed number so that it can be integrated into the traceability of the quartz resonator batches. This means that our production batch availability can be traced back to the incoming inspection of the quartz raw block. All in line with our sophisticated manufacturing process for clock generators of the highest quality, performance and service life.